-

Glass Balustrade Gate Hinge

Buy Now This product has multiple variants. The options may be chosen on the product page -

Glass Balustrade Gate Latch

Buy Now This product has multiple variants. The options may be chosen on the product page -

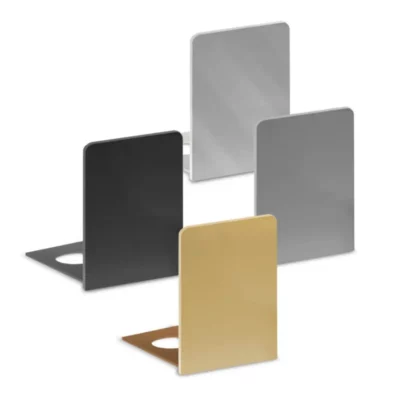

Glazing Channel End Caps

Buy Now This product has multiple variants. The options may be chosen on the product page- Glazing Channel Compatibility:

- Matt Black 2,400mm Glazing Channels

- Polished Brass 2,400mm Glazing Channels

- Polished Aluminium 2,400 Glazing Channels

- Brushed Nickel 2,400 Glazing Channels

- Finishes: Chrome polished, Brushed nickel, Black, Polished brass

- Application: Simply applied with a small amount of silicone sealant

- Glazing Channel Compatibility:

-

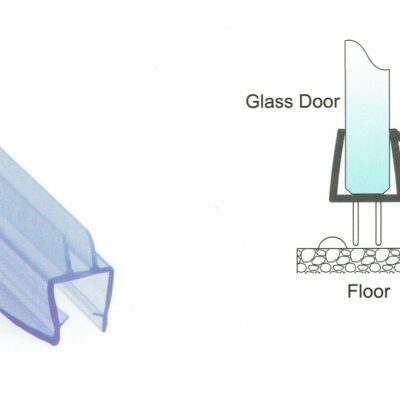

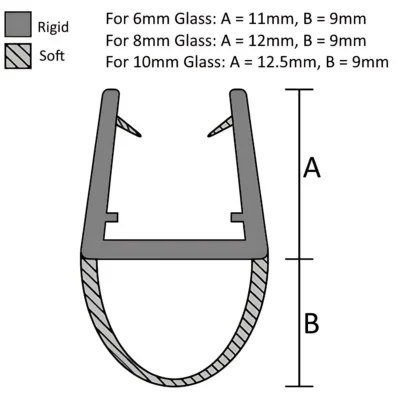

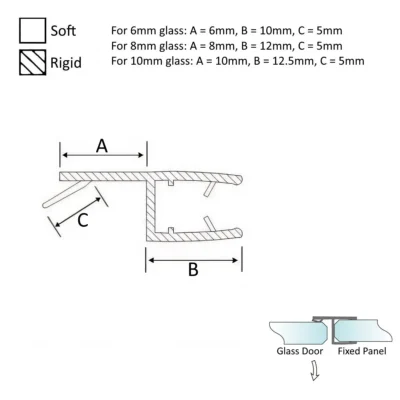

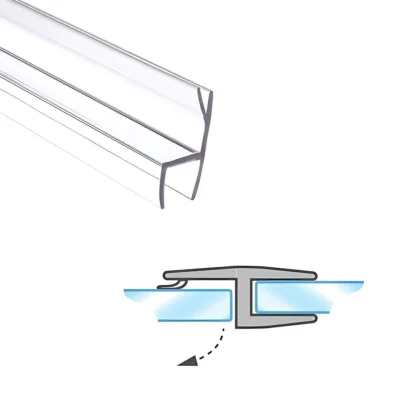

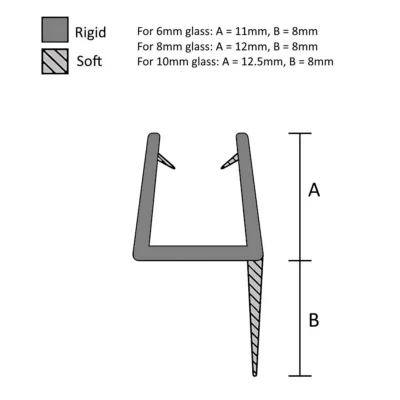

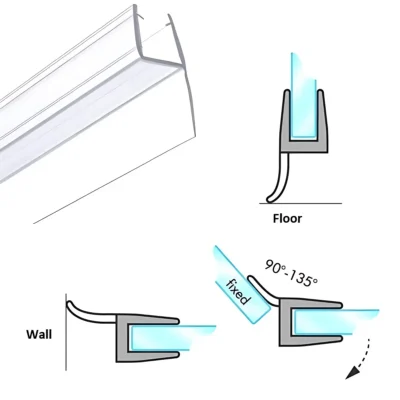

Translucent Glass Compression Seal 1000mm

Buy Now This product has multiple variants. The options may be chosen on the product page -

Translucent Glass Compression Seal 2500mm

Buy Now This product has multiple variants. The options may be chosen on the product page -

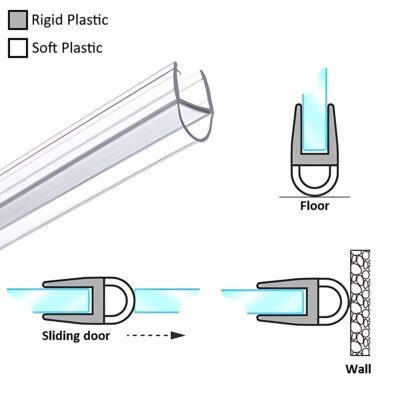

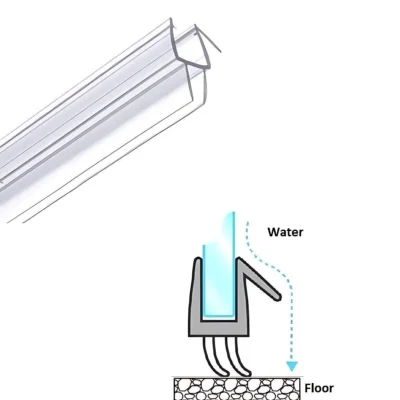

Translucent Glass to Floor Seals 2500mm

Buy Now This product has multiple variants. The options may be chosen on the product page -

Translucent Glass to Floor Seals 950mm

Buy Now This product has multiple variants. The options may be chosen on the product page -

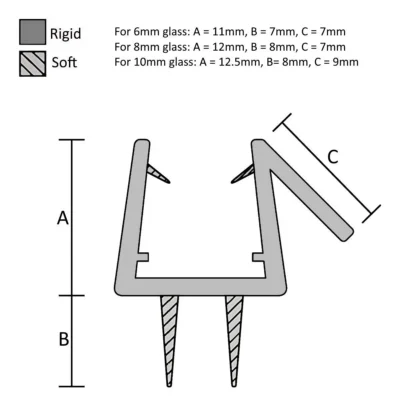

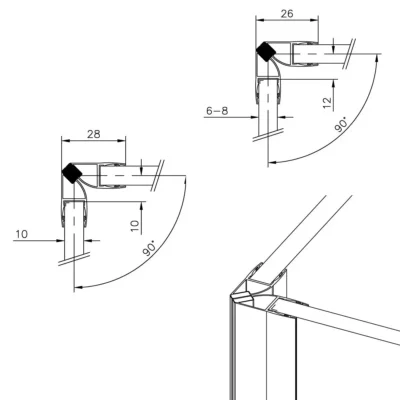

Translucent Glass to Glass Closure Seals

Buy Now This product has multiple variants. The options may be chosen on the product page -

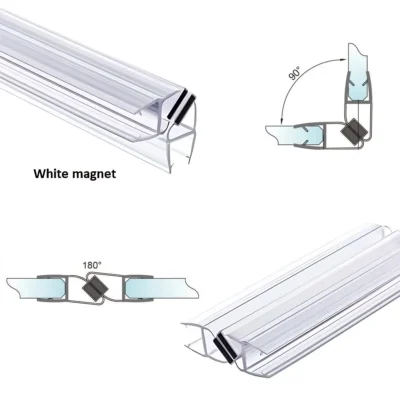

Translucent Glass to Glass Magnetic Seals

Buy Now This product has multiple variants. The options may be chosen on the product page -

Translucent Glass to Wall Seals

Buy Now This product has multiple variants. The options may be chosen on the product page -

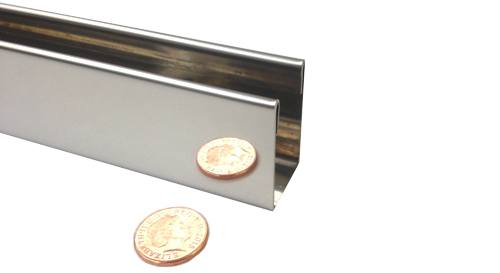

2,400mm Brushed Nickel Aluminium Glazing Channels

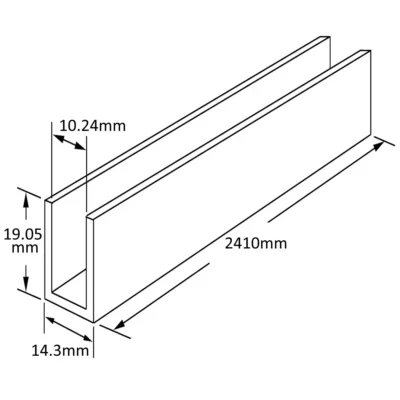

Buy Now- Dimensions: 14.3mm wide x 19.05mm height x 2,410mm long

- Glass compatibility: Suitable for 8mm – 10mm glass. (No Glass Preparation Required)

- Material: Extruded Aluminium.

- Finish: Brushed Nickle.

- Fitting type: Silicone fit.

- Suitable for Indoor and Outdoor Use.

- Suitable for Shower Enclosures, Wet Rooms, Bath Screens and General Glazing Restraint.

Can be used in conjunction with a clip in cover to create a continuous threshold from a fixed panel or continue a line to separate wall finishes without visible fixings.

Please note that these require cutting and drilling to suit on site.

-

Black 2,400mm Glazing Channels – 8mm – 10mm Glass

Buy Now- Dimensions: 14.3mm wide x 19.05mm height x 2,410mm long

- Glass compatibility: Suitable for 8mm – 10mm glass. (No Glass Preparation Required)

- Material: Extruded Aluminium.

- Finish: Black.

- Fitting type: Silicone fit.

- Suitable for Indoor and Outdoor Use.

- Suitable for Shower Enclosures, Wet Rooms, Bath Screens and General Glazing Restraint.

Can be used in conjunction with a clip in cover to create a continuous threshold from a fixed panel or continue a line to separate wall finishes without visible fixings.

Please note that these require cutting and drilling to suit on site.

-

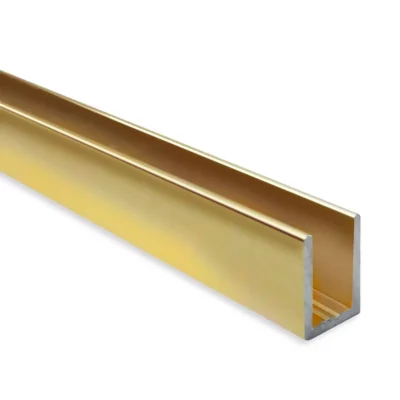

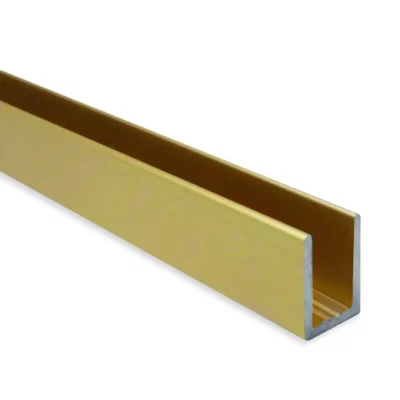

2,400mm Polished Brass Glazing Channels

Buy Now- Dimensions: 14.3mm wide x 19.05mm height x 2,410mm long – (PLEASE ENQUIRE IF YOU NEED A LONGER LENGTH)

- Glass compatibility: Suitable for 8mm – 10mm glass. (No Glass Preparation Required)

- Material: Extruded Aluminium.

- Finish: Polished Brass.

- Fitting type: Silicone fit.

- Suitable for Indoor and Outdoor Use.

- Suitable for Shower Enclosures, Wet Rooms, Bath Screens and General Glazing Restraint.

Can be used in conjunction with a clip in cover to create a continuous threshold from a fixed panel or continue a line to separate wall finishes without visible fixings.

Please note that these require cutting and drilling to suit on site.

-

2,400mm Electro Polished Aluminium Glazing Channels

Buy Now- Dimensions: 14.3mm wide x 19.05mm height x 2,410mm long

- Glass compatibility: Suitable for 8mm – 10mm glass. (No Glass Preparation Required)

- Material: Extruded Aluminium.

- Finish: Polished Aluminium.

- Fitting type: Silicone fit.

- Suitable for Indoor and Outdoor Use.

- Suitable for Shower Enclosures, Wet Rooms, Bath Screens and General Glazing Restraint.

Can be used in conjunction with a clip in cover to create a continuous threshold from a fixed panel or continue a line to separate wall finishes without visible fixings.

Please note that these require cutting and drilling to suit on site.

-

Brushed Brass 2,400mm Glazing Channels – 8mm – 10mm Glass

Buy Now- Dimensions: 14.3mm wide x 19.05mm height x 2,410mm long – (PLEASE ENQUIRE IF YOU NEED A LONGER LENGTH)

- Glass compatibility: Suitable for 8mm – 10mm glass. (No Glass Preparation Required)

- Material: Extruded Aluminium.

- Finish: Brushed Brass.

- Fitting type: Silicone fit.

- Suitable for Indoor and Outdoor Use.

- Suitable for Shower Enclosures, Wet Rooms, Bath Screens and General Glazing Restraint.

Can be used in conjunction with a clip in cover to create a continuous threshold from a fixed panel or continue a line to separate wall finishes without visible fixings.

Please note that these require cutting and drilling to suit on site.

-

Matt Black 2,400mm Glazing Channels – 8mm – 10mm Glass

Buy Now- Dimensions: 14.3mm wide x 19.05mm height x 2,410mm long

- Glass compatibility: Suitable for 8mm – 10mm glass. (No Glass Preparation Required)

- Material: Extruded Aluminium.

- Finish: Matt Black.

- Fitting type: Silicone fit.

- Suitable for Indoor and Outdoor Use.

- Suitable for Shower Enclosures, Wet Rooms, Bath Screens and General Glazing Restraint.

Can be used in conjunction with a clip in cover to create a continuous threshold from a fixed panel or continue a line to separate wall finishes without visible fixings.

Please note that these require cutting and drilling to suit on site.

Glass Fittings and Accessories

Glass Fittings and Accessories Results

Looking for high-quality door handles and knobs for your glass cabinets?

Maybe you’re on the hunt for clamps and brackets to complete your glass balustrade or hinges to help you complete a glass door installation?

Whatever accessories you need, we’ve got you covered here at Express Toughening.

We’re proud to offer a comprehensive range of top-quality glass fittings that are perfect for whatever project you’re working on.

Browse and shop our collection below or get in touch with our experts for help choosing the best glass fittings and accessories for your project!

A range of glass fittings and accessories at Express Toughening

From door knobs and handles to brackets, clamps, hinges, and more, our glass fittings are available in a variety of stunning finishes, including stainless steel, polished chrome and brass, and brushed nickel. So you’re bound to find something suitable for your glazing project, regardless of the glass thickness, type, weight, and everything else in between.

Express Toughening is the premier toughened glass manufacturer in the South East of England. Established in January 2001, we are a rapidly growing enterprise based within touching distance of the M25, offering a wide variety of glass products, as well as a complete range of hardware accessories to meet your requirements.

With premium quality products and unmatched customer service at our disposal, you really can’t go wrong when you shop with us.

Order glass fittings online at Express Toughening

Regardless of whether you’re fitting a glass shower screen in your bathroom or you’re looking to put the finishing touches on your modern glass balustrade, we’ve got everything you need to complete your project to the highest standard.

Scroll and shop our collection online today, adding everything you need to your online basket, and heading over to our secure checkout for convenient home delivery.

Alternatively, if you need help selecting the perfect fittings for your project, get in touch with our team today by calling 020 8500 1188 or emailing info@expresstoughening.com and we’ll get back to you with our recommendations!